Cardboard and salt might not go together on your palate, but they’re both key ingredients in what winds up on your plate. From haute cuisine culinary artists to the humble home chef, cooks around the country depend on the security and durability of paper packaging like corrugated cardboard and folding paper to bring their meals to life.

Paper’s strength seals its spot at the base of the food chain (and its antimicrobial properties don’t hurt either). “In transport, corrugated is king. Everything is being shipped in cartons and boxes, even fruits and vegetables,” says Soha Atallah, vice president of the World Packaging Organization.

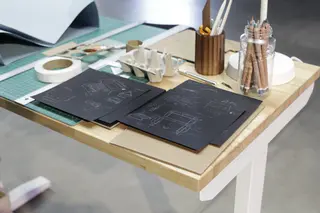

Food products have varying needs, including temperature and moisture control, breakage and weight. For instance, Terry Burga, account manager for transit packaging provider Signode, advises partners in the food packaging industry to use preformed corrugated pads for canned food. “It’s extremely strong, so it can handle a lot of weight.” But when dealing with a product that needs a different sort of security, like industrial-size multiwall sacks of flour, a different corrugated solution might be more appropriate.

Corrugated isn’t the only top chef in the food packaging industry, of course. Anti-slip papers, grip sheets and pallet papers keep food steady in long-haul transport—paper solutions most people never actually see yet show up on dinner plates across the country. More visible to more people are the paperboard boxes that house your morning cereal, the cartons that keep milk fresh and the boxes of small-batch cookies.

Corrugated’s versatility in everything—including making sure that food and drinks get to people safely and with ease—is remarkable. Coming in as a food packaging industry heavyweight: cardboard pallets, which are strong enough to support the weight of two rhinoceroses. And coming in as a corrugated ninja, providing protection in an unexpected way, is a material known as honeycomb.

Named for its resemblance to bees’ handiwork, honeycomb has a strong strength-to-weight ratio and shock absorbency. When Dan Fleek, a design engineer with honeycomb manufacturer Hexacomb, was challenged by a client who wanted to ship premium glass beverages, corrugated came into play. Instead of shipping the bottles in individual partitions, the client wanted to ship them as a shrink-wrapped unit. By using corrugated honeycomb, Fleek delivered a product that could be easily unpacked without breakage.

And perhaps most visible of all—or perhaps just the most appreciated: the vessels that keep online food delivery options chugging along. That bite of just-right pizza, those fries that arrive still crispy, that Chinese takeout container that gives you a built-in plate? That’s paper packaging, delivering its finest.

Learn more about Packaging, as well as the added benefits and solutions from our other industry associations on our Association Partners page.

View Association Partners