You use it in the morning to pour your milk and cereal, and at the end of the day when you order pizza for dinner. And if you’re a papertarian, you’re aware that cardboard is a responsible choice—made from a renewable resource and one of the most widely recycled materials out there.

But at some point, you might have wondered: How exactly is cardboard made? Lucky you: You’re about to find out.

What Is Cardboard?

Unless you’re in the paper and packaging industry, you probably use “cardboard” as a generic term to refer to most paper products that are thicker and heavier than paper. The sturdy boxes that your online deliveries come in, the thinner material that protects frozen meals, thick moving boxes meant for strength, the chic packaging from your local bakery—all are forms of paper packaging.

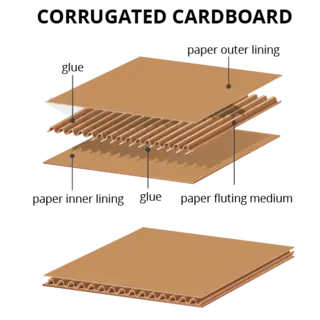

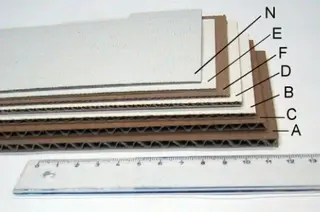

But within the industry, different terms emerge. The thinner, more flexible material that houses frozen meals and boxed pasta is referred to as paperboard. This means it has one layer of material, perhaps with a coating. The sturdier boxes that show up at your doorstep are corrugated cardboard, meaning that a wavy (or corrugated) layer of thick paper is sandwiched between two other flat pieces of thick paper, resulting in a sturdy material that can support more weight than paperboard alone.

The Origins of Cardboard

While there is one documented reference to a cardboard box before the 1850s, the cardboard box as we know it today originated in 1856, when two top-hat salesmen rigged up a prototype of corrugated cardboard to shape and strengthen their wares. In 1871, the first U.S. patent for corrugated cardboard was issued, and in 1879 a Brooklyn papermaker discovered that he could make his printing press cut and crease cardboard simultaneously, allowing for mass production of the cardboard box.

What Is Cardboard Made of? And How Is Cardboard Manufactured?

Cardboard is paper, so its manufacturing process begins in the same way as paper’s journey. Cardboard is made from trees that are purpose-grown mostly from private lands. Here in the U.S., more trees are planted than harvested each year. In fact, the volume of wood that’s planted and grown each year is nearly twice what is harvested. The trees as well as scraps from lumber mills are sliced into wood chips, which are pulped or broken down into a state where they become a liquid pulp solution for papermaking.

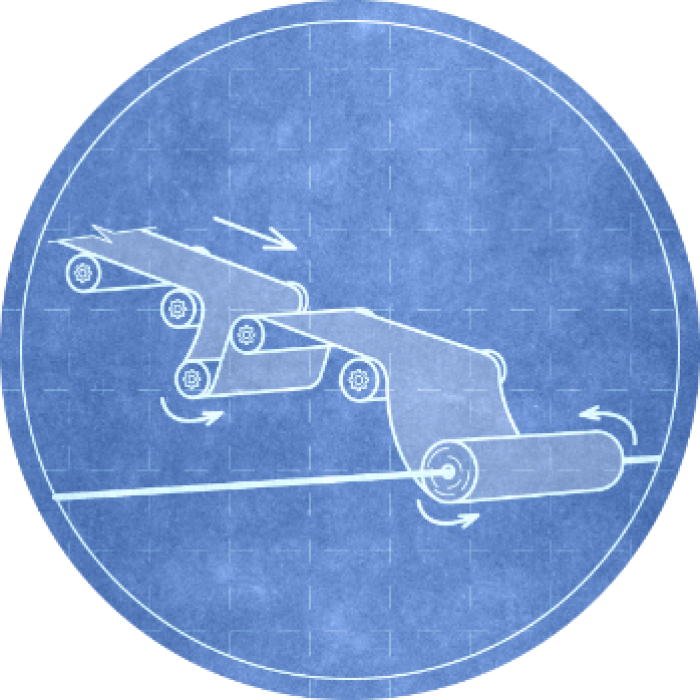

The pulp is run through a papermaking machine that drains the moisture from the pulp slurry while beginning to press the material into sheets. Through a series of belts and presses, the material continues to be dried and flattened to the appropriate thickness.

Many cardboard materials are made from recycled paper. Recycled cardboard is made by mixing used paper and packaging materials with water to create a slurry. Then, in a procedure similar to what happens with wood pulp, it’s dried and pressed until it’s in the right form for the next step.

Once the cardboard is recycled, it can be made into other products you use every day: cereal boxes, moving boxes, poster board, and takeout containers. Even though cardboard has been around since the 1800s, new developments in design and processes ensure that it continues to lead the way in packaging.

What Is a Corrugator?

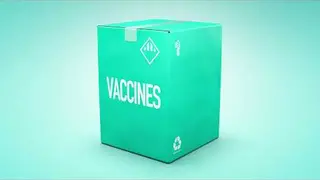

While the raw material of cardboard is created in much the same way as paper, for corrugated cardboard to arrive in its final form—sturdy yet with a degree of flexibility—it needs special treatment. Enter the corrugator, the machinery that produces corrugated cardboard from three layers of paperboard.

A corrugator crimps the middle layer of paperboard to give it its characteristic waves. This wavy material is glued between two flat pieces of paperboard with an adhesive. What emerges are large sheets of corrugated cardboard.

The cardboard process is similar to that of paper.

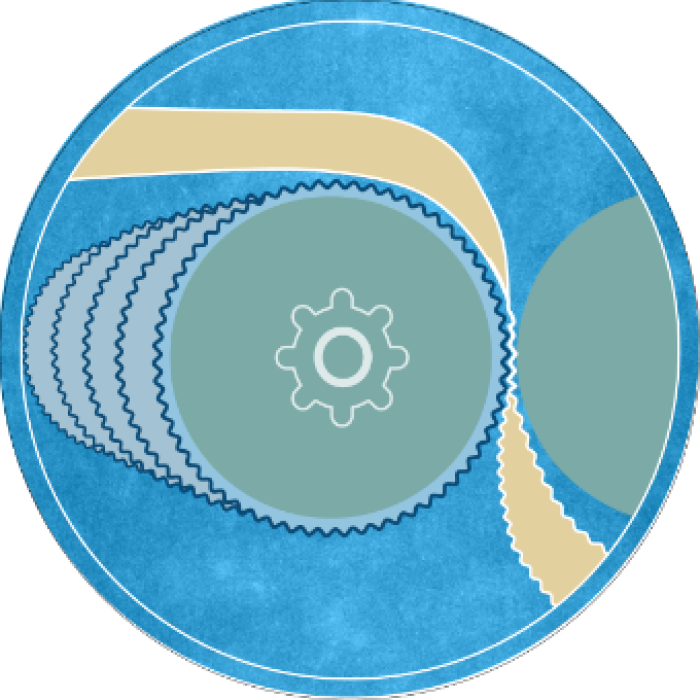

A corrugator created flutes in the material.

Different corrugators create different sizes of flutes.

What Are Flutes in Cardboard? What Are the Types of Flutes?

Flutes are what set corrugated cardboard apart from paperboard. The paper sandwiched between layers of flat paperboard features waves, or flutes. These give the finished product support without weighing it down.

The size of the flutes in corrugated cardboard varies. The largest flute, an A flute, is about 3/16 of an inch thick, providing superior cushioning for fragile products. The smallest flute you’re likely to see, an F flute, measures about 1/32 of an inch. Its thinness makes it easy to print on. Between these sizes are other flute sizes, all labeled by letter.

What Is the Environmental Impact of Cardboard?

Because cardboard is made from trees, it’s a part of a circular economy that begins with the earth. Today’s sustainable foresters start by growing trees with the intent of harvesting them. That devoted land means that the volume of wood from trees in the United States has increased—in fact, U.S. forests grow nearly twice the volume of trees that the industry harvests each year. And cardboard makers harvest only what they need, when they need it.

This leads to healthy, sustainable forests that serve as carbon sinks, wildlife habitats, and spaces of joy and connectivity.

And when you look at recycling rates, cardboard becomes an even more attractive option. Cardboard is the one of the most recycled material in the U.S., with 71-76% of corrugated cardboard being recycled in 2023.